what causes a trust bearing to fail in a 455 olds engine

If yous were lucky enough to take machine shop in high school, you lot might have been fortunate to exist able to "rebuild" one of the class engines. In those courses, you merely disassembled the engine and then reversed the process. Hopefully for the kickoff-timer, the engine started and ran happily and if so, yous passed the test. Nevertheless, for the true engine builder, assembly really is the easy part. It's all the checking and clearancing that is essential before the engine is assembled, where all the real effort is located.

Crankshaft endplay never seems to garner the same level of attending every bit say, rod and main clearance, but even with its somewhat express attention, this is nonetheless a crucial area. If nothing else, if crank endplay is not checked and verified, the cease result volition be disassembling the entire engine to repair the harm, because likewise loose is just as bad as too tight. This makes crank endplay a spec that cannot be overlooked, and that lone should motivate all but the laziest of engine builders.

We will be using both a small- and large-block Chevy for the images in this story, but the process is the same for all engines even when the thrust is located in the center principal begetting as with Fords and the GM LS. The thrust bearing incorporates both the journal begetting as well as fore-aft thrust surfaces. It is this clearance we volition be addressing in this article.

Setting The Stage

With a completely disassembled engine, the first step in this process is to ensure that the proper principal bearings are used. This sounds simple, only in the case of a contempo large-block Chevy, nosotros used 0.010-under bearings for the first four main bearings, and due to a slightly undersized Number Five creepo journal, this required a gear up of Federal-Mogul 0.011-inch-under bearings to ready the clearance on Number 5. In one case the proper principal begetting halves were selected, but then tin can we test for endplay.

Thrust clearance is important since there is a meaning amount of forward movement from both automated and transmission transmissions. Automatics are ofttimes blamed for burnt thrust bearings due to converter ballooning (expansion of the converter), and this does occur, simply there are other causes. I cause that receives very little attention is as well one that can be hands avoided.

Earlier checking endplay, y'all need to constitute the bearing clearance on the mains. That will determine the proper thrust bearing to be used. It does no adept to found crankshaft endplay, and and so have to bandy out thrust bearings to reach proper master clearance.

Manual transmission cars with the older way three-finger Long or Borg & Beck clutch pressure level plate designs, apply increasing pressure every bit the clutch pedal is pushed to the floor. This produces maximum forward thrust on the crankshaft while attempting to get-go the engine. Diaphragm pressure level plates go "over center" at full release which applies only express forward thrust. So the technique for a car equipped with a Long or Borg & Beck clutch is simply to beginning the engine in neutral. This eliminates potentially excessive wear on the thrust bearing.

Maximum Thrust

At that place'due south a simple technique for installing and measuring thrust bearings. For testing we start by installing the front end and rear bearings. For a Ford with the thrust in the center, y'all will need 3 bearings – the thrust and both finish chief bearings. With the bearings and creepo in place, gear up the chief cap in identify and lightly set the thrust cap with perhaps 10-xv lb-ft of torque on the bolts.

Using a rubber mallet, tap the crank forrard. This will align the two thrust bearing halves at the rear. Now torque the main cap bolts/studs with the oil pump, if and so equipped. At present we can measure the thrust clearance by get-go installing a dial indicator on the crank olfactory organ using a magnetic base. We pry back on crank using a long screwdriver, and then zero the dial indicator and then pry the crank lightly forrard to read the full clearance.

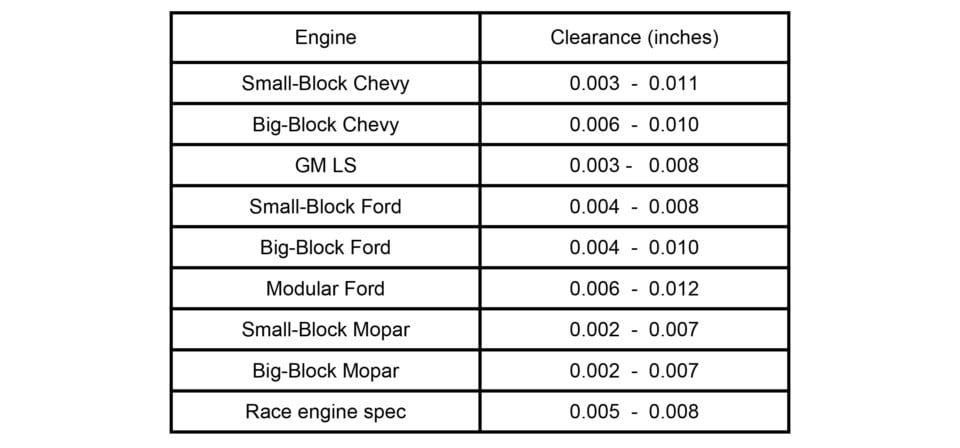

Each engine family has slightly different specs for crank endplay, but the majority of engine families fall in 0.004-0.008-inch range. We've created a nautical chart listing the pop V8 engines endplay clearances expressed equally a range. This puts the platonic clearance in the exact middle of the range. So for an engine with a range of 0.004 to 0.008-inch, the platonic spec would be 0.006-inch. Note that belatedly-model engines attempt to limit the maximum endplay, considering excess creepo movement can cause crank sensor errors.

Testing thrust clearance requires bearings in at to the lowest degree the Number 1 and Five journals to properly support the crankshaft. With the master cap in place lightly tap the creepo from behind to marshal the two bearing halves. This particular photo happens to be of a small-block (right). In the case of our big-block, the endplay came up shy of the minimum spec at barely 0.002-inch. This begetting will need to be sanded to add the necessary clearance, and get within the specs.

In the case of our big-block Chevy, with its new Number Five thrust begetting, nosotros measured barely 0.002-inch of endplay. This volition require us to sparse the bearing, which is much easier than having the crankshaft flange milled. The most common way to trim the thrust bearing thickness is to sand them.

Gaining Clearance

The bearing-thinning procedure starts past carefully placing a big stainless hose clamp around both thrust bearing halves with them sitting flat on a smooth surface. We use a 24-inch by 24-inch piece of scrap quarter-inch thick aluminum plate. We then measure the overall thickness of the thrust bearing finish to end using a dial caliper. Most functioning thrust bearings are now congenital with multiple small-scale ramps that change the "height" of the thrust slightly so it's important to measure in several areas to locate these ramps. We tape the widest number for reference.

We prefer to clamp the ii bearings halves together by setting them flush on a flat surface (an aluminum plate for case) and carefully tightening them with a large hose clench (left). We then use a dial caliper to measure the width of the begetting in several places and mark the widest portion with a Sharpie. We also marking the begetting on the side facing the rear so that all our sanding is achieved on the forward-facing side of the begetting (right).

Then we place a big piece of wet/dry 400-grit sandpaper on the aluminum plate and cover it with light automobile oil similar Marvel Mystery Oil. We mark the rearward facing side of the thrust bearing for reference and and then simply sand the reverse or forward or front-facing side. This maintains the original thickness on the rear side that volition receive the frontward thrust from the clutch or torque converter. Sanding in a effigy-eight motion, nosotros will sand for a minute or so and so cheque our measurements. This whole process may take ten to twenty minutes or more to complete.

Once the desired overall thrust thickness is achieved, sanding the bearing with a lighter one,000-dust or 1,500-dust paper tin can make the surface smoother. With all sanding complete, it's best to remove the stainless steel clamp and then thoroughly clean the bearing halves with alcohol and a lint-gratuitous paper towel. This is crucially important since that oily slurry which is left over after sanding is ridiculously abrasive and we don't want that going through the bearings.

There are a number of unlike abrasives that can be used. Nosotros used wet/dry 400 dust sandpaper lubed with Curiosity Mystery oil. Nosotros sand for a infinitesimal or two in a effigy-eight motion placing an even load past moving the position of the begetting in our hand. Annotation the arrow that points to the end to exist sanded. We terminate and measure every minute or so to check progress. In this case, we needed to remove roughly 0.004-inch of material to reach 0.006-inch of clearance.

After the begetting is clean, nosotros reinstall the bearing and go through the endplay cheque another time. If y'all've washed your math correctly, you should take an endplay clearance of somewhere near 0.006-inch as the number to shoot for.

In some cases where high loads might crusade increased thrust bearing wear, as with constant acceleration/deceleration with road racing or circle track applications, or with drag cars with transmission transmissions and high clutch loads, Mahle-Clevite suggests a minor modification to the rear thrust bearing. The accompanying photo shows the location of a minor 0.040-inch chamfer which tin be placed in the upper bearing half at the parting line on the side of the bearing closest to the thrust.

If thrust begetting wear or damage is an consequence, as evidenced from inspecting the former bearing, Mahle-Clevite suggests this minor modification: Locate the rear portion of the master bearing one-half in the block (upper) and carefully file a 0.040-inch chamfer at the parting line. This slight chamfer will pull additional oil onto the loaded (rear) side of the thrust surface which will improve lubrication and reduce the thrust surface temperature.

Just like all other engine clearances, the thrust clearance is disquisitional for proper engine performance. Even if sanding the thrust face is required, the task is non difficult or necessarily time consuming. The end result is a properly clearanced crankshaft, which ends up being its own reward.

A recheck of our endplay now reveals a clearance of 0.0065-inch, which is almost dead center between the factory recommendations for our big-block.

Source: https://www.enginelabs.com/engine-tech/blueprint-series-the-thrust-bearing-and-setting-crankshaft-endplay/

0 Response to "what causes a trust bearing to fail in a 455 olds engine"

Enregistrer un commentaire